The debate to choose between Investment casting and Metal 3D printing/Additive Manufacturing is quite complex. The decision cannot be taken independently without considering all factors relating to technical and monetary feasibilities.

To start with, businesses need to consider all factors of their production process and think thoroughly over it. Do you prefer faster lead times? Do you have a specific tensile, hardness and strength requirement of the part? Do you require a smooth surface finish?

You need to answer a host of such questions before choosing between an investment casting solution or a Metal 3D printing solution. Let us see the unique characteristics of both the manufacturing process so that you can make an informed decision.

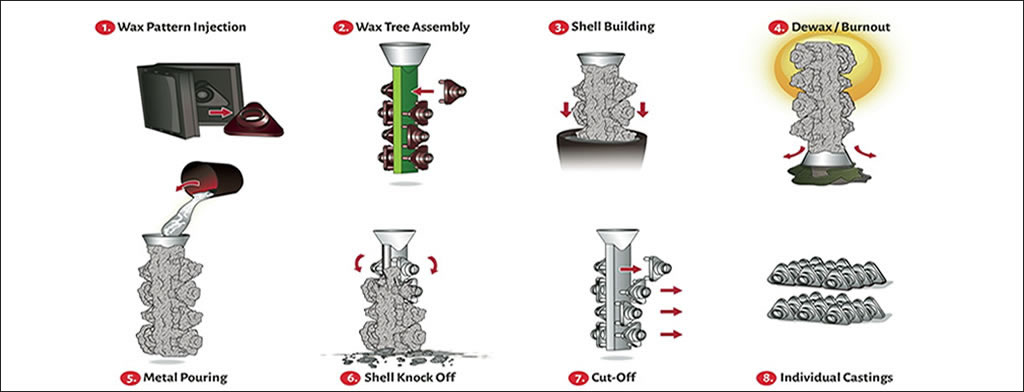

The traditional investment casting method is a very laborious and slow process. It requires a lengthy process that can take weeks and months to get the desired part if done completely offline. Once the part is in processing, there cannot be any changes to it. Any additional changes can prove to be costly as the entire production process will have to be repeated for the new part.

However, 3D printed patterns have quickened the process. It is now possible to make multiple iterations of the same part using 3D printed wax/polymer patterns during the assembly stage. Though this does save a significant amount of time and money, the procedure for investment casting remains the same. If there are stringent quality control measures which need to be implemented there can be additional steps to the entire process. Moreover, despite your best efforts, there can be chances of inconsistency in the parts produced as the whole process depends in part to the manual labour used in manufacturing the parts.

Metal 3D printing requires just a one-time investment in a technically appropriate 3D printer after which you can start to print your prototypes right away. You need to create a virtual design of the part that needs to be printed and then you can transfer the design to the 3D printer in a format that it will understand. Once done, the 3D printer will print the part accordingly. As compared to Investment casting, Additive Manufacturing takes way less time, is much more cost-effective and is of consistent quality than investment casted parts.

With the greater freedom that you have with regard to prototyping, you can afford to make as many samples as you need with a 3D printer. Though there are clear advantages, 3D printing is ideal for prototyping but will not be able to offer the economies of scale that investment casting does.

The study covered cost comparisons for 75 specific situations. To compare the two manufacturing methods side-by-side, 3 different part sizes (of 4,8 and 16 inches), 5 different parts of ascending complexity and 5 different production volumes were used. To get a realistic view, quotes were obtained from actual manufacturers of both investment casting and additive manufacturing for analysing the costs as the inputs changed.

The study found out that Additive manufacturing gets industry-average points for low volume production of small and complex parts. Using a hybrid model was found to be the middle-ground for both, while investment casting was popular where large and simple designs needed to be manufactured.