3D printing technology is slowly embracing all aspects of our lives, be it making vehicles, prosthetic limbs, engineering parts to even food.

Now, this technology can even be used to print the clothes we wear.

For new age fashion designers, 3D printing is the latest way they can express creative designs for a market always hungry for something new. In the world of fashion, haute couture is the best place for showcasing tailor made 3D printed apparels. In January this year, Dutch fashion designer Iris van Herpen showed off a 3D printed dress at the Paris Fashion week where she displayed her Spring/Summer collection 2018.

Though 3D printed apparels are an exciting proposition, the technology for the same is in its infancy. 3D printing still won’t replace knitting, weaving and other conventional means of apparel manufacturing soon, due to its high costs and current technical constraints.

Despite this, experts in the field foresee a distant future when we can print our clothes in the store, or maybe even at our homes. The best part of this is that you can have the garments printed just as per your body size and preferences-you could also design your clothes according to your pattern choices and colour customizations.

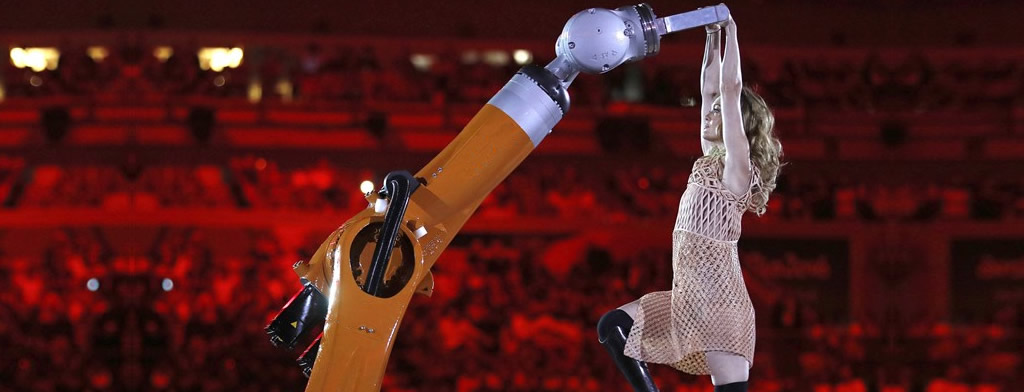

An Israeli fashion designer, Danit Peleg has shown how 3D printed clothing can look when you customize it for yourself, as she had made for American Paralympic snowboarder Amy Purdy who wore one of her 3D printed designs at the opening performance of the 2016 Paralympic Games in Rio De Janerio, Brazil. Many people assume that 3D printed clothes may be uncomfortable to wear, but she got it printed with a new material called FIlaFlex that fits the body well and is always comfortable to wear.

As mentioned earlier, convenience and customization are the biggest potential advantages of 3D printing, when recyclability is added to the mix, 3D printing becomes even more favourable.

Generally, old clothes are recycled by breaking them down and turning them into new fibres or selling them outright. However, it has been reported that a mere 0.1% of all fabrics are ever recycled, either by NGOs or by take-back programmes.

On the other hand, 3D printed clothes can be just dumped into a machine resembling a blender which will turn them into a powder which in turn, can be used for 3D printing clothes yet again.

However, there are several challenges for 3D printing clothing to becoming mainstream

Current 3D printers for printing apparel are extremely costly, they are beyond the reach of individual customers. The time taken to print a piece of clothing is also too much as against just buying one from the market which can be much more convenient to most people.

Also, there is the matter of comfort. Plastic made 3D printed clothing does not score brownie points for comfort; they may look glamourous on the ramp but wearing them on a daily basis just doesn’t really make sense.

Elizabeth Esponnette, a co-founder of on-demand clothing startup Unspun, says that it might take a few decades before 3D printed clothing becomes mainstream. As of now, 3D printed clothing will be seen more of a concept fashion trend rather than something that everyone can wear every day.

Recent innovations in 3D printing technology are showing the way forward. Some designers are creating flexible and softer fabrics by linking together many small pieces of 3D printed chainmail and other materials.

Meanwhile, many sport shoe companies are now incorporating 3D printed components in their products with Nike, Adidas and New Balance leading the pack. Within 10 years, it is estimated that 3D printed shoes will become mainstream, 3D printed apparel, however, may take a little longer to become an integral part of everyone’s wardrobes.