We were approached by a local brass manufacturer who wanted to sand cast a 5-foot tall lion statue from a one-foot sample that he provided us which he wanted to use for religious purposes. He came to us with a lot of hope, knowing well that if done with conventional methods, the entire 5-foot lion would take 4-5 months to prepare. We at STPL-VURO took this challenge head on and explained the entire process of 3D printing that we were going to use to make his dream a reality.

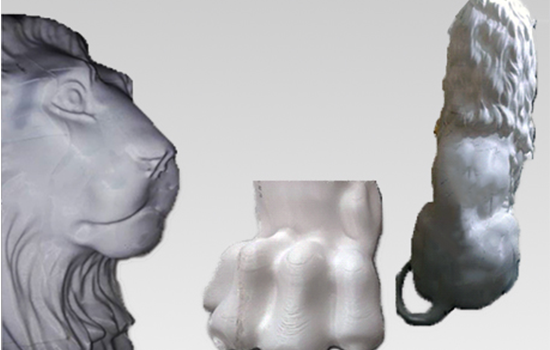

To start with, we did a thorough 3D scan of the one-foot lion sample that was provided to us. This gave us a virtual model of the object to be 3D printed for sand casting. With the help of our state- of-the-art 3D printing software, we then increased the dimensions of the lion as per the requirements of the customer. We then proceeded to 3D printing the entire 5-foot lion statue.

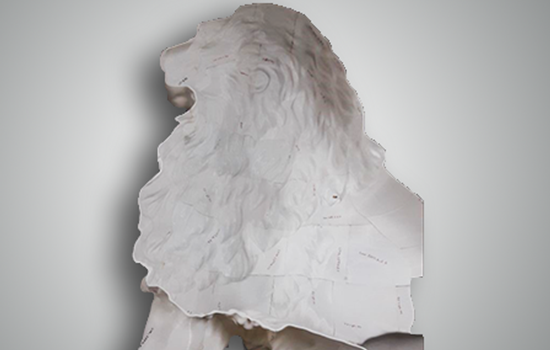

3D printing this mammoth 5-foot lion meant that we needed to divide the entire surface area of the lion into 127 different parts which were individually printed in our 3D printing machines using Fused Deposition Moulding(FDM) technology.

This entire process from 3D scanning the sample lion to 3D printing the various parts of the desired casting object and eventually assembling it all together, took a mere two weeks to implement. This is a far cry from the conventional methods used which take months to do the same and cost a bomb.

From our experience here at STPL-Vuro, we have realised that there isn’t much awareness about 3D printing in the market, even amongst machine tool manufacturers and metal statue makers like the one stated above. We aim to change this, to help small business owners save considerable time and effort in their sand casting businesses and use 3D printing whenever applicable to gain a competitive edge in the market.